Understanding Motor Position Sensor Prices: What To Expect When Shopping For Quality Sensors

When navigating the market for motor position sensors, it is crucial to grasp the myriad factors that influence their pricing. The diversity in technology, brand reputation, and manufacturing quality can result in significant variations, with basic sensors starting around $10 while advanced models may reach up to $500. Understanding these price ranges is essential for making informed decisions that balance budget constraints with the need for reliability and performance. However, the interplay between cost and quality does not end here; assessing long-term value could change your perspective entirely.

Understanding Motor Position Sensors

Motor position sensors are critical components in various applications, providing precise feedback on the angular position of a motor's shaft. These sensors play a vital role in enhancing the performance and efficiency of electric motors, ensuring accurate control in automation, robotics, and automotive systems. Understanding their functionality is essential for selecting the appropriate sensor for specific applications.

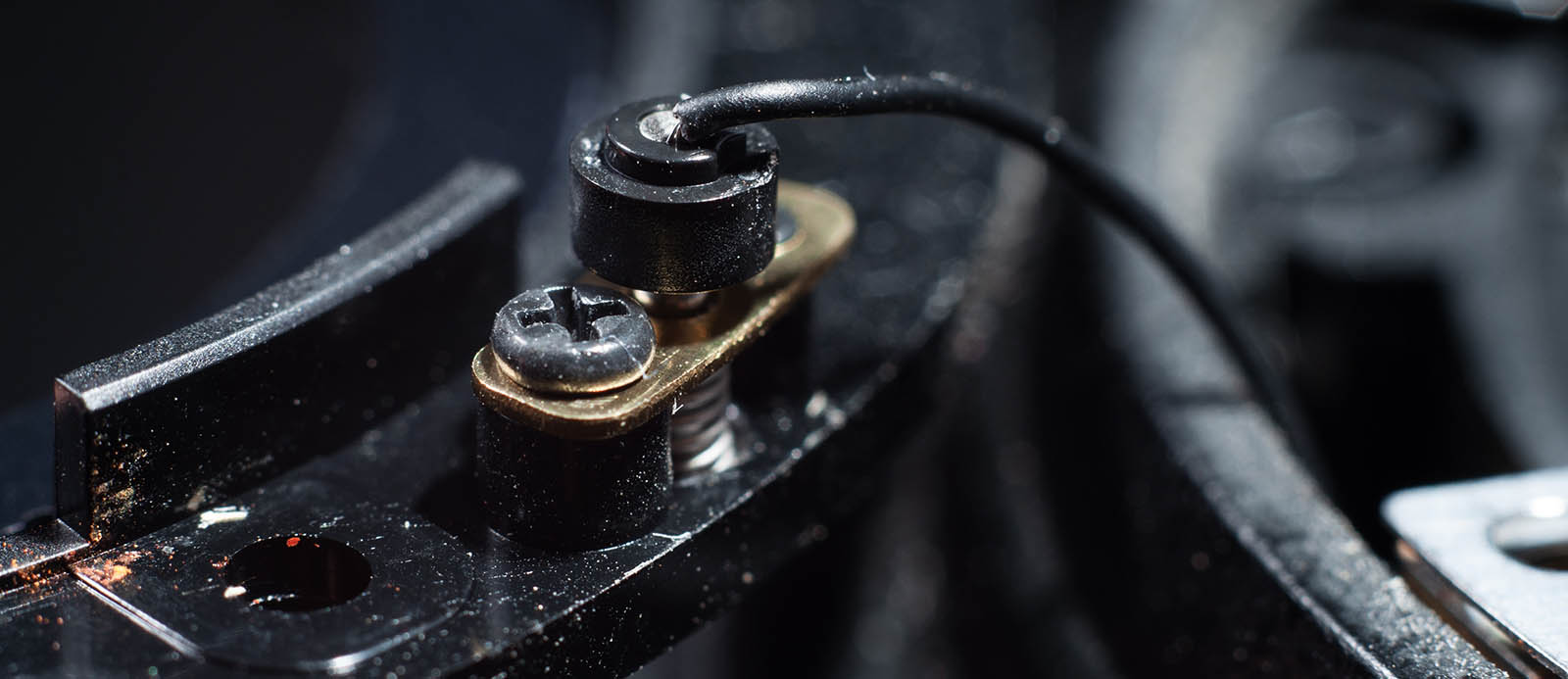

The sensor functionality typically involves detecting the position of the motor shaft through various technologies, such as potentiometric, optical, and magnetic sensing methods. Each technology offers distinct advantages, including resolution, response time, and environmental robustness. Choosing the right type requires careful consideration of the operating conditions and performance requirements.

The effectiveness of motor position sensors heavily depends on proper installation techniques. Correct alignment and secure mounting are crucial to ensure accurate readings and prevent mechanical interference. Additionally, appropriate wiring and connection practices are essential to minimize noise and signal degradation. By understanding both sensor functionality and installation techniques, engineers and technicians can optimize the performance of motor systems, leading to improved efficiency and reliability in their applications.

Factors Influencing Prices

Several factors influence the pricing of motor position sensors, making it essential for buyers to understand these variables before making a purchase. One primary factor is the level of technological advancements integrated into the sensors. Higher precision, better durability, and enhanced functionality often come with a premium price tag.

Brand reputation plays a significant role in determining costs. Established brands with proven reliability tend to charge more, reflecting the investment in research and development. Furthermore, the manufacturing process can affect pricing; sensors produced using advanced techniques or materials may be more expensive due to higher production costs.

Market demand also impacts prices. In times of increased demand, such as during industry shifts or technological upgrades, prices may rise. Conversely, price comparisons among various suppliers can reveal significant differences, enabling buyers to make informed decisions.

Geographical factors can influence shipping and import costs, which may be reflected in the final price. Understanding these factors enables buyers to navigate the market effectively and select the right motor position sensor that aligns with their budget and quality expectations.

Types Of Motor Position Sensors

Position sensors play a crucial role in various applications by providing accurate feedback on the location of a motor shaft. These sensors come in several types, each suited for specific operational needs.

Linear encoders are designed for measuring linear motion, providing precise position data along a straight path. In contrast, rotary encoders are used for rotational applications, offering feedback on the angular position of a motor shaft. Both types can be further categorized into incremental and absolute encoders, depending on their output signals.

Hall effect sensors utilize magnetic fields to detect position, making them ideal for contactless applications. This technology ensures durability and reliability, especially in harsh environments. Optical sensors, on the other hand, employ light to determine position, offering high precision but requiring a clean environment to function optimally.

Magnetic sensors provide a robust alternative, especially in applications where dust and moisture are present. Lastly, contactless sensors minimize wear and tear, enhancing sensor lifespan and reducing maintenance costs. Each type of motor position sensor presents unique advantages, allowing engineers to select the most suitable option for their specific applications.

If you search online for "motor position sensor price for sale," you'll discover a wide array of options that cater to various needs and budgets. The search results will likely showcase different types of motor position sensors, including rotary, linear, and digital sensors, each designed for specific applications in the automotive, industrial, and robotics sectors. Additionally, you'll find competitive pricing, allowing you to compare quality and features from various manufacturers and suppliers. Whether you're looking for high-performance sensors for precision applications or more affordable options for general use, the online marketplace offers a wealth of information and choices to help you make an informed decision. With data available up to October 2023, you can access the latest products and technologies in motor position sensing.

Average Price Ranges

The cost of motor position sensors varies significantly based on type, technology, and application. For instance, basic potentiometer-based sensors typically range from $10 to $50, while more advanced sensors, such as Hall effect or inductive types, can cost between $50 and $150. High-performance sensors, including optical or magnetic sensors with specialized features, may exceed $150, sometimes reaching $500 or more.

When conducting a price comparison, it is essential to consider not just the initial costs but also the long-term value and reliability of various sensor brands. Established brands often provide warranties and better customer support, which can justify a higher price point. Additionally, newer or less-known brands may offer competitive pricing but could lack the same level of quality assurance.

Quality Vs. Budget Options

While budget constraints often influence purchasing decisions, the quality of motor position sensors should not be overlooked. Investing in high-quality sensors can significantly enhance performance and reliability, ultimately leading to cost savings in the long run. Quality sensors are typically made from superior materials that withstand harsh operating conditions, ensuring they perform optimally over time.

Budget options may seem appealing due to their lower upfront cost; however, they often compromise on quality materials, which can result in increased wear and tear. Sensors constructed with inferior components may not only fail prematurely but can also lead to inaccuracies in motor positioning. This can cause significant operational disruptions, necessitating frequent replacements and repairs that negate any initial savings.

Quality motor position sensors are designed for longevity, reducing the frequency of replacements and the associated costs. Choosing a sensor that balances quality and budget requires careful consideration of the long-term implications of your investment. Ultimately, a focus on quality ensures that you select a sensor that will deliver reliable performance and longevity, safeguarding your operations against unexpected failures and expenses.

Tips For Smart Shopping

Smart shopping for motor position sensors involves several key strategies to ensure you make an informed decision. First, conduct thorough research on the various types of sensors available. Understand the specific requirements of your application, including factors such as accuracy, response time, and environmental conditions. This knowledge will help you identify suitable options that meet your needs.

When comparing prices, focus on sensor reliability rather than solely on cost. It's essential to evaluate the reputation of the manufacturer and read customer reviews. Reliable sensors may come at a higher initial price, but they often lead to lower long-term costs due to reduced maintenance and fewer replacements.

Another effective shopping strategy is to leverage online platforms and marketplaces. These platforms often provide comprehensive specifications and comparison tools that can aid in your decision-making process. Additionally, consider reaching out to industry professionals or forums to gather insights and recommendations.

Lastly, take advantage of promotions or bulk purchase discounts. By following these smart shopping strategies, you can ensure that you select a high-quality motor position sensor that provides both performance reliability and cost-effectiveness.

Contact A Motor Position Sensor Supplier Today

Navigating the landscape of motor position sensor prices requires careful consideration of technology, quality, and brand reputation. Balancing budget constraints with the pursuit of reliability and investing in higher-quality sensors yields long-term benefits. Understanding the diverse types of sensors and their respective price ranges empowers informed decisions. Ultimately, prioritizing operational efficiency and performance leads to enhanced productivity and reduced maintenance costs. A strategic approach to shopping ensures optimal choices in the realm of motor position sensors.

UniMeasure Inc. stands out as a leading provider of precision measurement solutions, demonstrating a commitment to innovation, quality, and customer satisfaction. With a diverse range of products and services tailored to meet the needs of various industries, the company has established a strong reputation for reliability and accuracy. As it continues to leverage advancements in technology and expand its market presence, UniMeasure Inc. is well-positioned to address the evolving demands of its clientele. Moving forward, the company's focus on research and development, along with its dedication to sustainability and operational excellence, will likely ensure its continued success and growth in the competitive landscape of measurement solutions.